Site: Gudai-Darri

Client: Rio Tinto

Service: Rope Access, Scaffolding, Structural, Mechanical & Piping

Capability: Maintenance, Shutdown

Industry: Mining and Resources

Scope of Work:

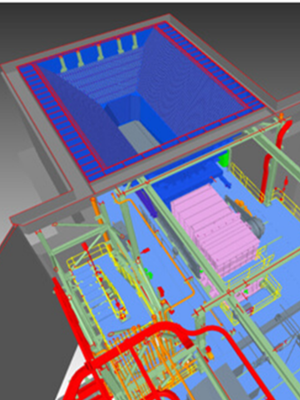

Breight Group was engaged by Rio Tinto to perform essential maintenance on the 622 DEX Hopper at the Gudai-Darri site. The scope of work involved replacing worn rail sections, installing new ceramic liners on the back wall, and performing parent metal repairs.

The rail replacement was divided into two sections: the upper and lower rails, both of which were showing significant wear. The lower sections, located on the left and right-hand walls as well as the back wall, required replacement with new sections. Careful planning ensured that the rails were pre-drilled offsite to match the bin’s design, streamlining the installation process and minimizing onsite cutting and drilling. A scaffold was erected outside the bin to facilitate easy access for bolt work, while rigging and rope systems were set up to safely lower the worn rail sections and bring in new ones using the overhead crane inside the bin.

In addition to rail replacement, the project scope included replacing the ceramic liners and performing repairs on the parent metal. The removal of the worn ceramic liners was carried out using specialised tooling, followed by a thorough inspection of the parent metal. Any damaged sections were cut out and replaced with new mild steel sections to restore the integrity of the bin.

Throughout the shutdown, safety was a top priority, with measures in place to mitigate the risks posed by ongoing crusher work above the team. Breight Group’s team worked seamlessly to ensure the maintenance was completed without compromising safety or efficiency, and all tasks were completed on schedule.

Key Activities Completed:

- Pre-drilling of rail sections offsite to ensure a precise fit

- Installation of scaffold outside the bin for easy access to bolts

- Safe removal and replacement of worn rail sections using the overhead crane

- Replacement of ceramic liners with parent metal repair

- Thorough inspection and replacement of damaged parent metal sections

- Coordination of rail replacement and liner work to avoid operational disruptions

- Completion of all work with full compliance to safety standards

Related Projects